1

/

of

1

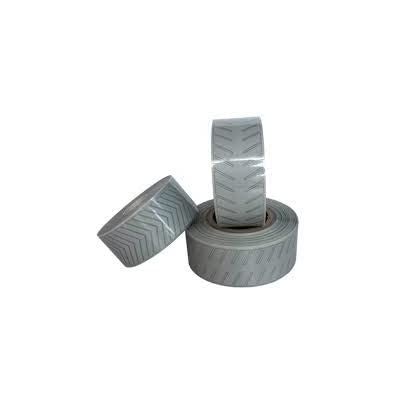

Iron On Reflective Heat Transfer Film For Patterned

Iron On Reflective Heat Transfer Film For Patterned

JustInTrend

Regular price

$9.11

Regular price

$13.74

Sale price

$9.11

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

SKU: SUPREFTAPEHT-13

MATERIAL & CONSTRUCTION:

- Type: Iron on / Heat Transfer (this product is intended only to heat transfer on fabric or similar surfaces. This may not sew on or stick to any products)

- Backing Material: PET film with hot melt adhesive

- Retroreflective daytime fabric color - Silver

- Weight: 6 – 7 oz

DESIGN & SIZING

- Recommended for Medium to heavy Weight Fabrics, such as high-quality safety vest or jackets.

- Machine washable, shrink resistant, wrinkle resistant, quick drying, durable colors.

- Retroreflective sizing options

- 1” width Silver – 2.54 cm wide retroreflective material

- 2” width Silver – 5.08 cm wide retroreflective material

- 4” width Silver – 10.16 cm wide retroreflective material

COMPLIANCE

- ANSI / ISEA 107-2015 – American Standard on High Visibility Safety Apparel

- CSA Z96 – Canadian Standard on High Visibility Safety Apparel

- Other Certifications – EN 20471

- Home Wash Cycles: > 50 cycles @60℃(140℉)

- Reflective coefficient: >420

WASH / CARE INSTRUCTIONS.

- Machine washable

- Shrink resistant

- Wrinkle resistant,

- Quick drying,

- Durable colors

APPLICATION INSTRUCTIONS

- Things needed: An ironing mat or a similar material (example towel), a nice solid table, your project (example T-shirt) and the heat transfer vinyl tape

- Application

- Flip your image

- Cut and weed - The goal when cutting heat transfer vinyl is to not cut through the clear carrier sheet (shiny side). This plastic sheet acts like transfer tape, keeping your design tacked down to your fabric while pressing. It also protects the fabric from the direct heat of the press or iron.

- Pre-Press Your Fabric - Get that fabric nice and warm before attempting to apply the vinyl. Heating up the fabric open the fibers, allowing the adhesive from the vinyl to really absorb into the material during the press. So go ahead and press your fabric for 2-3 seconds with your iron/heat press

- Temperature + Pressure + Time -

- Not all vinyl has the same heat setting, and it is crucial to your success to follow your manufacturer's heat setting recommendations. Typically, a cotton-blend setting with temperatures in 350-375 deg F range will work for most applications.

- The next part of the HTV application equation is pressure. If using an iron, you need to really put your weight on the iron while you're pressing. Make sure your pressing surface is hard and can handle having you press with all you might on it.

- Finally, make sure you know the ideal pressing time. 10-15 seconds is the typical pressing time. You don't want to scorch the adhesive by keeping the heat on too long and over pressing.

- Know when to peel - Changes slightly by the type of application and tape.

- If not sure, ALWAYS check out YouTube instructional videos and do a tryout on a small sample.

Share